How an Optical Fibre Diameter Analyser Boosts High Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes stands for a significant development in top quality control methods. By using real-time, specific dimensions of Fibre diameters, this innovation attends to the crucial need for uniformity in manufacturing requirements.

Relevance of Fibre Diameter Dimension

Precise measurement of Fibre Diameter is vital in the field of optical Fibre modern technology, as it directly affects the performance and integrity of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capability, depletion, and general transmission performance. Accuracy in measuring Fibre Diameter makes sure that the optical properties are maintained within specified tolerances, which is important for optimal signal integrity.

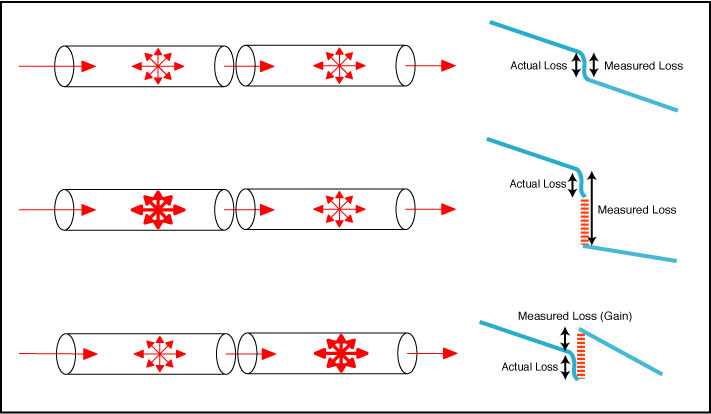

Variants in Fibre Diameter can cause increased losses as a result of scattering and modal diffusion, impacting the quality of information transmission. In high-speed interaction systems, such inconsistencies can cause significant deterioration of signal high quality, resulting in data errors and decreased performance. Additionally, constant Fibre Diameter is important for compatibility with connectors and splicing innovations, which are indispensable parts of Fibre optic networks.

Quality control procedures in Fibre production heavily depend on precise Diameter measurements to make certain compliance with industry requirements. By carrying out robust measurement techniques, makers can enhance item dependability, reduce waste, and improve total system efficiency. Therefore, the significance of Fibre Diameter measurement can not be overemphasized, as it acts as a cornerstone in the innovation of optical Fibre modern technology and its applications in contemporary interaction networks.

How the Analyser Works

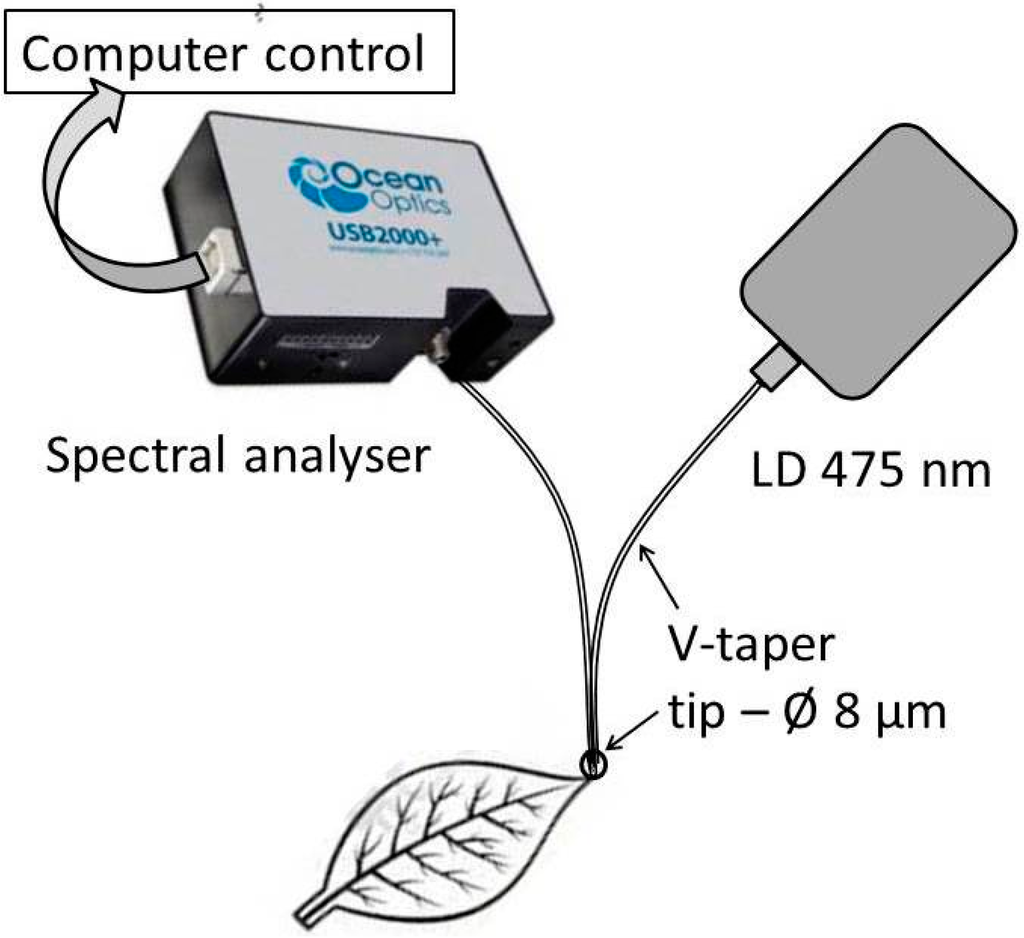

The effective dimension of Fibre Diameter depends on advanced analytical strategies that make sure precision and integrity in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a mix of laser modern technology and progressed photo processing formulas to precisely analyze the Diameter of fibres as they are created

Originally, a laser beam is routed at the moving Fibre, developing a cross-sectional shadow. The analyser captures this shadow using high-resolution cameras placed strategically along the manufacturing line. The captured pictures are then refined in real-time to determine the Fibre's Diameter with phenomenal accuracy.

The system makes use of innovative algorithms that account for different elements, consisting of variants in light strength and ecological problems, to improve measurement reliability. It can discover minute modifications in Diameter, such as fluctuations that may happen throughout the manufacturing process.

Furthermore, the analyser can dealing with numerous fibers concurrently, enhancing throughput without endangering accuracy. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an important duty in preserving rigorous quality assurance requirements, making sure that the end product meets industry specifications and customer demands.

Advantages of Real-Time Surveillance

While typical methods of keeping an eye on Fibre Diameter commonly involve lengthy post-production checks, real-time monitoring considerably enhances the efficiency and top quality of optical Fibre production. optical fibre diameter analyser. This positive technique permits manufacturers to determine inconsistencies in Fibre Diameter as they happen, rather than waiting up until production is complete to examine high quality

By constantly measuring the Diameter during manufacturing, manufacturers can ensure that the fibres fulfill rigorous specifications, causing decreased variability and improved consistency. Real-time surveillance additionally enables prompt corrective actions to be taken, reducing waste and stopping defective fibres from getting in the supply chain.

Furthermore, this modern technology promotes improved data collection and analysis, providing insights right into production trends and potential locations for improvement. Such data-driven decision-making equips producers to enhance procedures and keep high criteria of high quality control.

Additionally, real-time surveillance cultivates a culture of continual enhancement within the production setting. Employees are much more engaged when they can see the impact of their job in real-time, leading to increased accountability and a dedication to excellence. On the whole, the application of real-time monitoring systems in optical Fibre manufacturing translates to exceptional product quality and enhanced consumer satisfaction.

Effect On Manufacturing Effectiveness

Carrying out optical Fibre Diameter analysers considerably enhances production effectiveness by streamlining the production process. These devices help with constant monitoring of Fibre Diameter, enabling producers to find discrepancies in real-time. By determining incongruities promptly, production lines can be changed swiftly, decreasing downtime and lowering the possibility of generating faulty products.

Additionally, the combination of these analysers into the production workflow makes it possible for better resource appropriation. With accurate Diameter measurements, drivers can maximize material use, guaranteeing that resources are not lost on flawed fibres. This accuracy also contributes to less remodel and junk, eventually decreasing production costs.

The automation provided by optical Fibre Diameter analysers basics decreases dependence on manual assessments, which are usually taxing and prone to human error. Consequently, workers can concentrate on even more critical jobs, boosting general performance.

Furthermore, the data produced from these analysers can educate procedure enhancements and facilitate much better decision-making. By examining trends in Fibre Diameter variations, makers can apply aggressive measures to enhance production techniques and preserve consistent high quality. In summary, optical Fibre Diameter analysers play a critical role in boosting production efficiency, resulting in higher quality outcome and enhanced earnings.

Study and Success Stories

Throughout numerous industries, study highlight the transformative effect of optical Fibre Diameter analysers on production processes. One prominent instance is a leading telecommunications company that encountered obstacles with irregular Fibre diameters, resulting in increased being rejected rates. By incorporating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, causing a 30% decrease in issues and substantial price financial savings.

Furthermore, a study organization concentrating on sophisticated products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's ability to give in-depth understandings into Fibre consistency made it possible for the advancement of cutting-edge materials with better performance attributes.

These success stories highlight the essential function of optical Fibre Diameter analysers in boosting quality assurance, enhancing manufacturing efficiency, and driving technology across diverse sectors.

Conclusion

To conclude, the Optical Fibre Diameter Analyser plays a critical duty in enhancing high quality control within Fibre production. By giving precise, real-time measurements and promoting immediate restorative activities, this modern technology considerably minimizes irregularity and minimizes waste. The application of such sophisticated helpful resources devices cultivates a culture of continuous enhancement and functional effectiveness, inevitably ensuring compliance with industry requirements and preserving competition. As shown via numerous study, the analyser proves vital for accomplishing remarkable item top quality in Fibre manufacturing.

The implementation of from this source optical Fibre Diameter analysers enabled for stringent high quality control, ensuring that the created fibres satisfied exacting industry requirements.In conclusion, the Optical Fibre Diameter Analyser plays a critical duty in enhancing high quality control within Fibre production.

Comments on “How an Optical Fibre Diameter Analyser Contributes to the Development of Future Fibre Optic Systems”